21. 11. 2024

Atypical solution: affordable mobile metal detector in cable and connector manufacturing (case study)

Initial status

The world's largest manufacturer and supplier of cable and connector technology uses rubber tubing of various diameters in an endless roll.

Problem

When manufacturing connectors and cable harnesses, quality comes first. The customer had to deal with complaints arising from the metal contamination of the rubber tubing. There was in fact only a random occurrence of these metallic (magnetic as well as non-magnetic) contaminants due to which whole batches were claimed. The consequences were high costs and deterioration of customer relationships.

The manufacturer therefore required a reliable metal detection solution. At the same time, however, he emphasized low acquisition costs, as more machines needed to be protected by the detectors.

Another requirement was the detector mobility and its easy relocation between production lines (according to the material currently being processed on the production line).

Solution

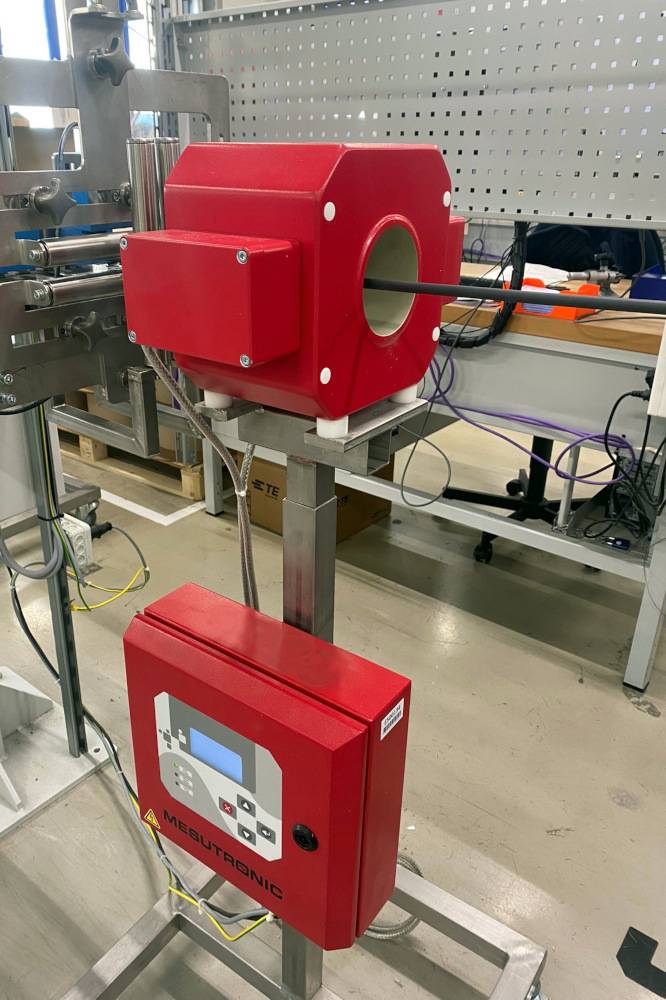

At SOLLAU, we design solutions according to customer requirements. In this case, we tried to apply a completely new solution. We used the METRON 05 CR gravity metal detector, which is originally designed for the detection of metal contaminants in bulk materials gravitationally transported in pipelines. We have combined the advantages of this detector, such as the perfect metal detection and the attractive price.

At SOLLAU, we design solutions according to customer requirements. In this case, we tried to apply a completely new solution. We used the METRON 05 CR gravity metal detector, which is originally designed for the detection of metal contaminants in bulk materials gravitationally transported in pipelines. We have combined the advantages of this detector, such as the perfect metal detection and the attractive price.

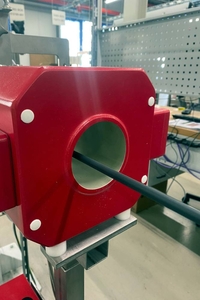

The detector was placed on a frame fitted with locking wheels. We have equipped the mobile frame not only with a detection head, but also with a control unit. Such a detector is completely autonomous and it can be easily relocated between workplaces. The rubber tubing in an endless roll passes through the detector aperture where it is inspected for the presence of metal particles in order to immediately afterwards the next production technology.

First, we provided the customer with a prototype of this device so that he could thoroughly test it in the production line. After successful tests, we delivered alle the needed devices.

We are proud that we have managed to find a powerful and mobile detection solution at an attractive price!

Benefits of using the metal detector METRON 05 CR

The customer is satisfied with the supplied detectors because they can detect metal contamination more reliably than the competing detectors previously used.

All complaints caused by metal contamination of the rubber tubing have been completely eliminated.

The customer also appreciated that we met his additional requirements - a low price and a mobile design of the detector.

The customer also appreciated that we met his additional requirements - a low price and a mobile design of the detector.

Applied equipment: metal detector METRON 05 CR

Advantages of the metal detector METRON 05 CR

- Digital signal processing for best detection

- 4 button touchpad controls

- Intuitive and simple operation

- Gravity detector for installation in pipes with a diameter of 35 - 600 mm

- Low height and compact dimensions

- Economical variant - attractive price/performance ratio