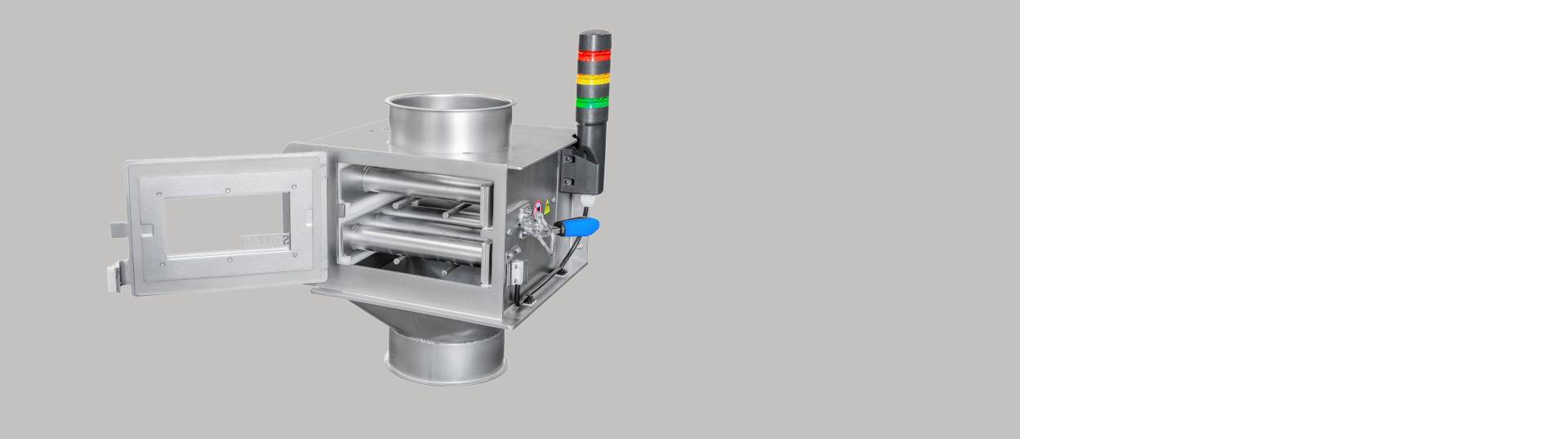

Drawer magnets with indication of magnet saturation MSS-MC ALARM

The magnetic grate separator alerting when the magnet has reached the level of saturation with ferromagnetic contaminants gives a reliable answer to the question when the operator has to clean the magnet. It is a known fact that the magnetic separation efficiency of a magnetic grid clogged with ferrous particles is significantly reduced.

How to find out when to clean the magnetic separator?

The alarm light provides customers with clear and understandable information about when the magnetic separator needs to be cleaned, as well as when it is not necessary to perform the cleaning. This leads both to a dramatic increase in the magnetic separation quality and to the optimized labor productivity. The operator doesn't have to shut down the entire production line to determine if the magnetic separator needs to be cleaned!

The light signal gives the operator information about the magnetic separator efficiency at three levels - 100%, 50% and 0%.

SOLLAU, as a technological leader in the development of magnetic separators, brings a solution how to indicate and signal the magnet saturation as the first in Europe!

We consider magnetic separators with contamination signaling as another significant step in the development of magnetic separators - since the widespread use of strong neodymium magnets in separators about 30 years ago.

7 + 1 Reasons Why to Choose a Magnetic Separator with Contamination Signaling at the Alarm Output

If the magnetic separator grids are clogged with trapped metals, the separation efficiency will decrease. After reaching a certain saturation limit, the separator can no longer capture ferrous contaminants. The saturation alarm ensures that the separator is cleaned in time and operates at maximum efficiency.

Until now, there was no way for an operator to know that a separator needed to be cleaned. The ALARM system signals the need for separator cleaning, leading to reduced downtime, increased production continuity and capacity. Knowing when to clean the separator is just as important as knowing when not to clean it.

The signaling gives clear information to the operator that the separator needs to be cleaned.

The operator cleans the separator only when it is really needed. This leads to increased productivity - operators can perform duties other than checking magnets.

Clear visualization of the need for cleaning results in better supervision over the production process. Quality auditors simply love the ALARM system!

Timely cleaning increases the separation quality, i. e. fewer quality complaints, delivery rejections and lower complaint costs.

Contaminant detection protects production technology from damage = lower maintenance costs.

Investing in the ALARM system brings a permanent reduction in operating costs and an increase in production efficiency.

Indication of the magnet saturation

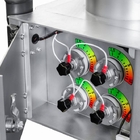

The ALARM metal control gives the operator reliable and clear information about the need for separator cleaning and significantly reduces human errors! It is signaled by colored LED lights on the separator door or by a beacon.

The ALARM metal control gives the operator reliable and clear information about the need for separator cleaning and significantly reduces human errors! It is signaled by colored LED lights on the separator door or by a beacon.

The drawer magnet consists of two magnetic grids placed one above the other. The ALARM system allows for the magnet saturation indication of each grid. This provides the operator with detailed information about which grid is clogged with the ferrous contaminants.

What do the different colored lights indicate?

- Green light (100 % separation efficiency) - both magnetic grids are clean and free of ferrous contaminants. The magnetic separator is fully functional.

- Orange light (50 % separation efficiency) - the upper magnetic grid is clogged with ferrous particles and needs to be cleaned. The separation efficiency is lower. The lower magnetic grid continues to provide full magnetic power. This information gives the operator time to schedule a production shutdown and clean the separator. We recommend cleaning as soon as possible!

- Red light (0 % separation efficiency) - the lower magnetic grid is clogged with dirt and needs cleaning. The separation efficiency is insufficient! The separator does not perform its function and must be cleaned immediately!

The MSS-MC ALARM separator is equipped with permanent magnets, i. e. it performs its separating function even during a power failure.

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

Sensor position setting

MSS-MC ALARM magnetic separators are used for different types of materials. There are also different requirements for the purity of the cleaned material, and the size of the separated ferrous particles varies as well. Some customers require separation of micron-sized particles, for others, it is enough to remove larger ferrous contamination.

MSS-MC ALARM magnetic separators are used for different types of materials. There are also different requirements for the purity of the cleaned material, and the size of the separated ferrous particles varies as well. Some customers require separation of micron-sized particles, for others, it is enough to remove larger ferrous contamination.

Therefore, the distance between the sensor and the magnetic grid can be set from 1 to 10 mm.

The sensor distance can be adjusted individually for each magnetic grid (i. e. a different sensor distance from the upper and a different distance from the lower magnetic grid).

Magnetic Separator Cleaning

The cleaning of the magnetic separator with the ALARM system is identical to that of the standard MSS-MC separator. During the cleaning the grids can be taken out of the separator and afterwards cleaned very easily and quickly (as the ferromagnetic particles drop away off the grid surface spontaneously as soon as the magnetic cores are manually pulled out of the stainless steel protective tubes).

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

- Indication of magnet saturation

- Individual sensor settings for each magnetic grid

- Two-stage separation

- Removable grids

- 18,700 Gauss on the magnetic core and 12,200 Gauss on the stainless steel protective tube

Which industrial branches can the grate magnet in housing be used in?

Drawer magnets are mostly used in the area of recycling and waste treatment, food processing, pharmaceutics, wood processing, plastic industries, mining and mineral processing, industrial production of ceramics and glass etc.