Gravity free-fall style metal detector QUICKTRON 05 A

The highly sensitive gravity style QUICKTRON 05 A metal separator is used to detect and reject metal contaminants from bulk materials gravitationally transported in pipelines. The detector is fully automatic, equipped with a high-speed reject flap that instantly diverts the contaminant from the product stream and minimizes the loss of a good product.

The advantageous price and high sensitivity make the QUICKTRON 05 A the most often used gravity style metal detector used to check free flowing gravity fed bulk materials.

Digital signal processing enables excellent detection results and the robust detector design contributes to its maximum lifetime.

The QUICKTRON 05 A detector is easily integrated into existing installation thanks to its low overall height and compact dimensions.

We supply this gravity free-fall style metal separator for pipes with a diam. of 50 – 300 mm as standard. We can also offer this detector for pipes of other diameters and shapes (square, rectangular).

The open frame construction allows unlimited accessibility to all components for easy cleaning.

This detector is equipped with a powerful AMD 05 control unit with a range of advanced functions such as automatic product setup, automatic calibration, or the digital filtration system. The unit is fitted with a 5-line LCD display and controlled by 4 ergonomic buttons. Its operation is simple and intuitive. The control unit is installed on the detector frame, but it can be also placed outside the detector.

Principle advantages of a gravity free-fall style metal detector

- Metal detector for inspection of bulky material during free fall. All metal particles are detected and it is both off-shell particles and the ones in the form of inclusions in the end product.

- Extremely exact and reliable detection of metals.

- Resistant and robust – favourable investment.

- Versions with the ATEX certificate are available.

- Compactness making the integration into already existing production plants and lines easier.

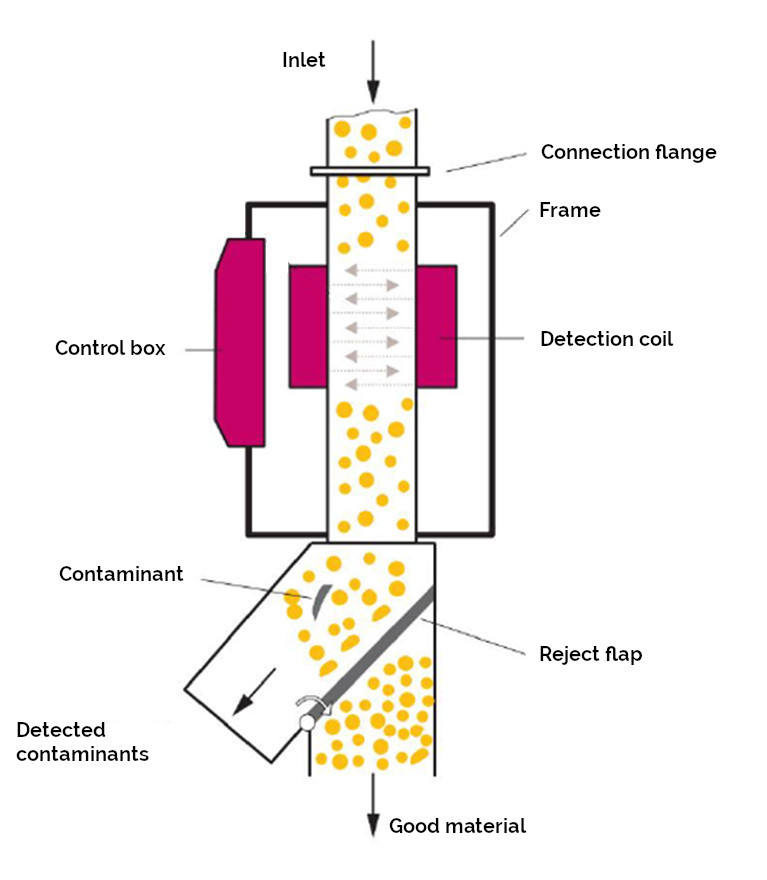

Working principle

The metal detector of the Quicktron series is installed in a pipeline, transporting free-falling bulk material. The inspected material passes through the reject assembly. If the material is contaminated with metal particle(s), the contaminant in the product stream alters the high frequency field generated by the search coil. The electronics evaluate this signal and generate an impulse for the solenoid valve and double actuating air cylinder of the reject assembly. The contaminant is instantly diverted from the good product stream assuring minimal good product loss. The reject flap then automatically returns to its normal position. The detector operation including the elimination of contaminants is fully automatic.

The metal detector of the Quicktron series is installed in a pipeline, transporting free-falling bulk material. The inspected material passes through the reject assembly. If the material is contaminated with metal particle(s), the contaminant in the product stream alters the high frequency field generated by the search coil. The electronics evaluate this signal and generate an impulse for the solenoid valve and double actuating air cylinder of the reject assembly. The contaminant is instantly diverted from the good product stream assuring minimal good product loss. The reject flap then automatically returns to its normal position. The detector operation including the elimination of contaminants is fully automatic.

Thanks to the high-speed reject flap, its operation is very fast and accurate enabling minimization of the loss of good material.The reject time is adjustable - In the case of several metal particles being present, the reject time will be extended accordingly to assure a metal free product..

The QUICKTRON 05 A gravity free-fall style metal detector is:

- Reliable – in process and detection

- Durable – in technology and performance

- Flexible – in size and use

Optional equipment

The QUICKTRON 05 A detectors can be supplied with a wide range of additional equipment:

- Signal units – beacon, buzzer, beacon with siren

- Extended self-monitoring - air pressure, diverter function

- Air compressor

- Compressed air tank

Special design

Do you have special requirements for a metal detector design? The most common requirements include:

- Stainless steel version

- Version for overpressure applications up to 0.3 bar

- High temperature versions

- Units painted to customer specific color code

- Explosion proof versions

- Detector with the control display and/or control unit in a separate box

Materials employed

- Frame – stainless steel (1.4301 / SS 304)

- Detection coil - aluminum, optionally stainless steel (1.4301 / SS 304)

- Control box – sheet steel, as an option stainless steel (1.4301 / SS 304)

- Cover plate – PP (polypropylene)

- Sensor tube – PP (polypropylene), as an option TIVA

- Connection flange - stainless steel (1.4301 / SS 304)

- Reject flap - stainless steel (1.4301 / SS 304)

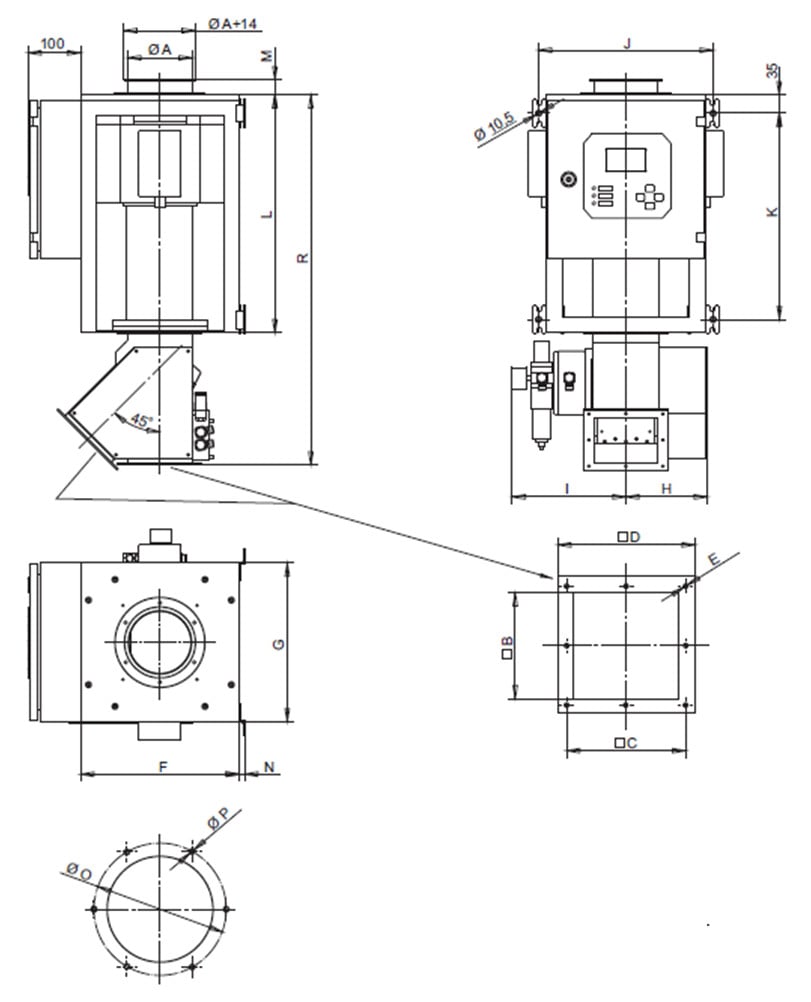

Dimensions

| A: (mm) | B: (mm) | C: (mm) | D: (mm) | E: (mm) | F: (mm) | G: (mm) | H: (mm) | I: (mm) |

|---|---|---|---|---|---|---|---|---|

| 50 | 70 | 86 | 100 | 8xM5 | 220 | 300 | 100 | 180 |

| 70 | 70 | 86 | 100 | 8xM5 | 220 | 300 | 100 | 180 |

| 80 | 120 | 140 | 160 | 8xM5 | 300 | 300 | 154 | 215 |

| 100 | 120 | 140 | 160 | 8xM5 | 300 | 300 | 154 | 215 |

| 120 | 120 | 140 | 160 | 8xM5 | 300 | 300 | 154 | 215 |

| 150 | 200 | 225 | 246 | 8xM5 | 370 | 370 | 203 | 255 |

| 200 | 200 | 225 | 246 | 8xM5 | 430 | 430 | 203 | 255 |

| 250 | 300 | 325 | 360 | 8xM5 | 530 | 530 | 322 | 180 |

| 300 | 300 | 325 | 360 | 8xM5 | 630 | 630 | 322 | 180 |

| J: (mm) | K: (mm) | L: (mm) | M: (mm) | N: (mm) | O: (mm) | P: (mm) | R: (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| 250 | 260 | 310 | - | - | 72 | 4xM5 | 490 | 25 |

| 250 | 260 | 310 | - | - | 130 | 4xM5 | 490 | 25 |

| 330 | 340 | 400 | 35 | 10 | 108 | 6xM5 | 650 | 35 |

| 330 | 340 | 400 | 28 | 10 | 130 | 6xM5 | 650 | 40 |

| 330 | 390 | 450 | 28 | 10 | 150 | 6xM5 | 700 | 45 |

| 380 | 405 | 470 | 36 | 5 | 180 | 6xM5 | 800 | 55 |

| 460 | 605 | 670 | 37 | 5 | 230 | 6xM5 | 1000 | 65 |

| 560 | 605 | 665 | 48 | 5 | 280 | 6xM5 | 1200 | 130 |

| 660 | 805 | 865 | 50 | 5 | 366 | 8xM10 | 1400 | 160 |

We can supply units with different height, inside diameters, frames, etc. to meet your requirements.

We will ask you to specify the required modifications so that the offer can be elaborated exactly according to your requirement.

Sensitivity of a metal detector

The detector sensitivity depends on many parameters, such as the aperture diameter (the smaller the aperture, the higher the sensitivity), the material speed, the density of the product, its temperature, humidity, etc.

Maximum obtainable sensitivity can be established by testing your product sample in our laboratory. We will perform these tests free of charge. Please contact us, we will discuss the test execution as well as the dispatch of your material samples.17.03.2022

The QUICKTRON 05 A sensitivity diagram:

| Model | 50 | 70 | 80 | 100 | 120 | 150 | 200 | 250 | 300 |

|---|---|---|---|---|---|---|---|---|---|

| Sensitivity – steel ball dia. (mm) | 0,3 | 0,45 | 0,5 | 0,6 | 0,7 | 0,9 | 1,0 | 1,5 | 1,75 |

AMD 05 Control unit

A first-rate control unit is essential for the proper functioning of any detector. Our control unit is made with an emphasis on the high quality of workmanship and of the employed components.

The result is a stable control unit with a wide range of functions (just to name a few):

The result is a stable control unit with a wide range of functions (just to name a few):

- Control unit (of single board design) with built-in regulated power supply for reliable performance and ease of service

- Auto-balance including the suppression of interfering signals and automatic sensitivity calibration

- Multi-filter system using digital filtration for maximum stability in harsh environments

- Narrow detection zone provides an accurate location of the metallic particle in the detection field allowing precise separation

- Self-monitoring system ensures that all important components function properly

- Easy 4-button intuitive operation

- 5-line back-lit LCD display

- Product storage memory backup – for up to 500 products

Scope of delivery

The delivery of QUICKTRON 05 A detectors includes:

- Detection head

- Reject unit including pneumatic components such as air pressure regulator, etc.

- Control unit (= electronics mounted in a metal cabinet)

- Connecting cables

- Installation hardware

- User manual

- Power supply: 100 – 240 V AC, 50/60 Hz

- Power consumption: max. 50 W

- Type of protection: IP 66 (IP 69 K)

- Min. working temperature: - 10 °C

- Max. working temperature: + 50 °C

- Relative air humidity: 0 – 95 % (without condensation)

- The conveying speed at which metals can be reliably detected: 1,5 – 6,0 m/s

- Power cable: 1.8 m with plug