Magnetic conveyors MD

Magnetic conveyors are used for transporting ferromagnetic components as well as scraps. Thanks to their design, even sharp or oiled parts can be handled easily and safely. Permanent magnets are chain driven under a non-moving stainless steel slider bed. Ferrous objects are therefore caught by the magnetic field at the beginning of the slider bed and carried to its end.

The advantage of magnetic conveyors is that they do not have any external moving parts (in contrast to the standard belt conveyors or conveyors with plastic modular belts) – that is why the transported objects do not damage the conveyor. The beltless magnetic conveyor has a closed design, so it is resistant to dust and can be used for transporting oiled parts.

Magnetic conveyors are most frequently used in these areas:

- Metal pressing plants - handling of metal stampings

- Automotive industry – sheet metal handling, transport of components and stampings

- Machine works – removal of steel chips, shavings and scrap from machining

- Foundries – handling of hot castings

We manufacture two basic types of magnetic conveyors:

- Straight style magnetic conveyors - for horizontal transport of steel parts

- Inclined (Z-shaped) magnetic conveyors - for inclined transport pf steel parts

Thanks to the design of the magnetic conveyor, we can manufacture it in practically any length.

How to choose the right strength of magnets?

We equip beltless magnetic conveyors with different types of magnets. We select suitable magnets according to the characteristics of the part to be transported (its weight, dimensions etc.). We also take into account the requirements for the conveyor height and the temperature of the transported parts.

For the vast majority of applications, a magnetic conveyor with ferrite magnets is suitable. Its advantage is the attractive price. For specific parts or when a low working height is required, we equip the magnetic conveyor with the strongest neodymium magnets.

According to the part dimensions we design the suitable spaces between the magnets of the conveyor.

"We do not make any experiments!" We propose a functional solution!

In our test center we have magnetic conveyors with various kinds of magnets and different spaces between the magnets. This enables us to CARRY OUT THOROUGH TESTS OF YOUR PARTS and to design the most suitable magnetic conveyor.

We guarantee fast performing tests!

We know well what is important to our customers - smooth and trouble-free operation of the magnetic conveyor!

That is why we design the conveyors to be sufficiently robust. We take care of their high-quality workmanship.

We also think about making their maintenance easy and quick for the operators. Therefore, the basic equipment of every magnetic conveyor includes:

- Automatic drive chain tensioning

- Peephole with a watermark for checking the oil level

- Easy oil drainage

- Oil funnel for easy oil filling

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

Magnetic conveyor design

The core of the magnetic conveyor consists of a chain conveyor, on which there are transversely placed magnets. The magnet strength and spacing between the magnets depend on the specification of the parts to be handled.

Ferrous objects are caught by the magnetic field at the beginning of the conveyor and carried to its end, where they fall off spontaneously.

The chain conveyor is completely covered - the transported parts are in contact only with the stainless steel slider bed.

The oil reservoir of magnetic conveyor ensures self-lubricating and trouble-free operation of the components inside the conveyor.

We will adapt the supporting structure under the conveyor to your requirements.

What do we need to know to design a magnetic conveyor correctly?

- Size of transported parts

- Weight of transported parts

- Material from which the transported components are made

- Required hourly capacity

- Needed length of magnetic conveyor

- Distance from the floor where the conveyor is to be placed

- If the parts need to be transported to a different height, it is necessary to specify the starting and target height and the arrangement of the surrounding machines connected to the magnetic conveyor

- Photo of the place where the conveyor is to be used

An application form filled in by you would also help us a lot and that is why we will send the form to you immediately upon request.

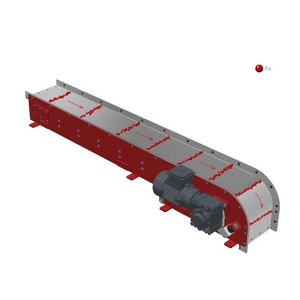

Straight magnetic conveyors

Straight magnetic conveyors are used for the horizontal transport of ferrous objects. Thanks to the design of the magnetic conveyor, we can manufacture it in practically any length.

We manufacture straight magnetic conveyors in standard widths of 200, 300, 400, 500 and 600 mm, but in case of a specific customer request, we can manufacture a magnetic conveyor in a different width as well.

We equip magnetic slide conveyors with ferrite (weaker) or neodymium (stronger) magnets. The advantage of magnetic conveyors with neodymium magnets is their low height, what also required by some clients or applications.

We can also supply magnetic conveyors in a “HOT” version – i. e., for high temperatures. We select the type of the needed magnets according to the maximum temperature of the transported objects.

MD – F VIPER

- Ferrite magnets

- It is suitable for most applications

- Standard magnetic conveyor widths - 200, 300, 400, 500 and 600 mm

- This magnetic conveyor can be produced also in other widths

- Attractive price/performance ratio

- Max. operating temperature up to 80 °C

MD – N VIPER

- The strongest neodymium magnets

- It is suitable for transporting very small or large and heavy parts

- Suitable also for applications where a low working height of the conveyor is required

- Standard magnetic conveyor widths - 200, 300, 400, 500 and 600 mm

- This magnetic conveyor can be produced also in other widths

- Max. operating temperature up to 80 °C

MD – VIPER HOT

- For high temperature applications

- The type of magnets is selected according to the required operating temperature and the specification of the transported objects

- Standard magnetic conveyor widths - 200, 300, 400, 500 and 600 mm

- This magnetic conveyor can be produced also in other widths

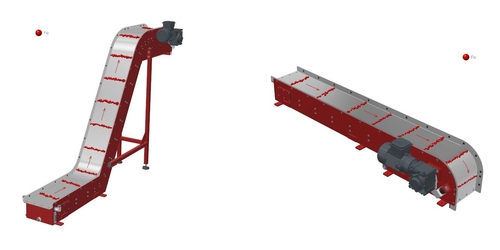

Inclined (Z-shaped) magnetic conveyors

Angled magnetic conveyors are used for the inclined or vertical transport of ferrous objects. They find their application where parts need to be transported to a height different from the starting one. For a correct specification of an inclined magnetic conveyor, we need to know not only the size, weight, and quantity of transported parts but also the starting and target height.

Angled conveyors can be supplied in the same way as straight ones:

- They can be made in virtually any length

- Standard widths: 200, 300, 400, 500 and 600 mm

- In case of a specific customer's requirement, we can also produce the magnetic conveyor in other than standard widths

- They are equipped with ferrite (weaker) or neodymium (stronger) magnets

- We can also supply them in a “HOT” version – i. e., for high temperatures

MD – F COBRA

- Ferrite magnets

- It is suitable for most applications

- Standard magnetic conveyor widths - 200, 300, 400, 500 and 600 mm

- This magnetic conveyor can be produced also in other widths

- Attractive ratio price/performance

- Max. operating temperature up to 80 °C

MD – N COBRA

- The strongest neodymium magnets

- It is used for the transport of very small or large and heavy parts

- Suitable also for applications where a low working height of the conveyor is required

- Standard magnetic conveyor widths - 200, 300, 400, 500 and 600 mm

- This magnetic conveyor can be produced also in other widths

- Max. operating temperature up to 80 °C

MD – COBRA HOT

- For high working temperature applications

- The type of magnets is selected according to the required operating temperature and the specification of the transported part

- Standard magnetic conveyor widths - 200, 300, 400, 500 and 600 mm

- This magnetic conveyor can be produced also in other widths

Which industrial branches can the magnetic conveyor be used in?

The magnetic chip conveyor finds use in metal working, metal cutting, transport of smaller pressed pieces etc.