Metal detector for vibratory conveyors METRON 05 VT

The metal detector METRON 05 VT is designed to be installed directly into the vibratory troughs. Thanks to the detector design it can be installed extremely quickly and easily in a conveyor of any shape.

Another advantage is that the detector installation does not require a metal free zone. These facts make it a universal metal detector for installation in vibratory conveyors. It is often used for detecting metals in wood processing.

The METRON 05 VT dominates the market also thanks to its attractive price/performance ratio.

Principle advantages of a tunnel metal detector

- Metal detector for a direct installment into the conduit of vibrating feeder..

- All metals both free and hidden in the material are detected

- Reliable preservation of the machinery thanks to high sensitivity of the detector.

- Quick and easy assembly.

- Minimum investment costs.

- Suitable solutions for all common types of vibratory cinduits.

- Practical, reliable and by running of many years proven technology.

Installation

The METRON 05 VT metal detector for vibratory conveyors is designed to be easily and quickly installed in a conveyor of any shape.

The METRON 05 VT metal detector for vibratory conveyors is designed to be easily and quickly installed in a conveyor of any shape.

The METRON 05 VT metal detector for vibratory conveyors is:

- Reliable – in process and detection

- Durable – in technology and performance

- Easy – in installation and handling

Optional equipment

The METRON 05 VT detectors can be supplied with a wide range of additional equipment:

- Signal units – beacon, buzzer, beacon with siren

- Remote reset of the device

- Visual marking of the detected contaminants = color coding

- SW modifications according to your needs – data transfer, specific check operations

Special design

Do you have special requirements for a metal detector design? The most common requirements include:

- Detection head and control unit housing in stainless steel design

- Ingress protection code: IP 65

- Units painted to customer specific color code

- Special power supply and termination boxes etc.

- ALUTRON version – suppression of interference signals from metalized foils – Patent No. 4342826

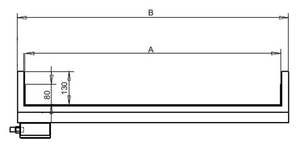

Dimensions

| A: Inner width (mm) | B: Detector width (mm) |

|---|---|

| 300 - 1000 | A + 60 |

Metal free zone - MFZ

The great advantage of this metal detector is that a metal-free zone is not required.

Contact us – we will help you with the MFZ calculation for moving and fixed metals.

Sensitivity of a metal detector

The detector's sensitivity depends on many parameters, such as the aperture dimensions (the lower is the aperture height, the higher is the detector sensitivity), the conveyor belt speed, the density of the product, its temperature and humidity, etc.

The detector's sensitivity depends on many parameters, such as the aperture dimensions (the lower is the aperture height, the higher is the detector sensitivity), the conveyor belt speed, the density of the product, its temperature and humidity, etc.

Maximum obtainable sensitivity can be established by testing your product sample in our laboratory. We will perform these tests free of charge. Please contact us, we will discuss the test execution as well as the dispatch of your material samples.

The sensitivity diagram of the METRON 05 D detector applies to LB 1,5 x LH

AMD 05 Control unit

A first-rate control unit is essential for the proper functioning of any detector. Our control unit is made with an emphasis on the high quality of workmanship and of the employed components.

The result is a stable control unit with a wide range of functions (just to name a few):

The result is a stable control unit with a wide range of functions (just to name a few):

- Auto-balance including the suppression of interfering signals and automatic sensitivity calibration

- Multi-filter system using digital filtration for maximum stability in harsh environments

- Self-monitoring system ensures that all important components function properly

- Touch screen control panel – modern design

- Easy 4-button intuitive operation

- 5-line LCD display

- Product storage memory backup – for up to 500 products

- Metal detector network and remote service - diagnostics, parameter change, SW update

Scope of delivery

The delivery of METRON 05 D detectors includes:

- Detection head

- Control unit

- Connecting cables

- User manual

- Power supply: 100 – 240 V AC, 50/60 Hz

- Current consumption: max. 50 W

- Type of protection: IP 54 (optionally IP 69K)

- Min. working temperature: - 10 °C

- Max. working temperature: + 50 °C

- Relative air humidity: 0 – 95 % (without condensation)

- Max. conveyor belt speed, at which metals can be reliably detected: 30 m/s (higher speed version available on request)

- Power cable: 1.8 m with plug