Mobile magnetic filters MSP-S ANCISTRUS

Mobile magnetic filter MSP-S ANCISTRUS is designed to separate tiny iron contamination from machining oils and coolants.

Main benefits for the use of separator MSP-S ANCISTRUS

- Extension of the life of cutting, cooling and hydraulic fluids

- Precision finish of machined products

- Cost savings in disposable filter usage

- Reduced waste disposable and oil wastage

- Extension of (e. g. machine) tool life

- Overnight fluid cleaning beyond normal working hours

- Extension of the life of pumps and nozzles

- Reduction of maintenance costs

- Reduced downtime

- Permanent protection of the production equipment

- Smooth production operation

- Thanks to its compactness and mobility, this filtration system is ideal e. g. for companies providing engineering service

Customer care

Your project will be taken care of by us from beginning up to the very end. It does not end with the order placed at us. We will provide the full support for all the time of the use of the separator.

1. We will come

2. We will align and design

3. We will make a made-to-measure product

4. We will install

5. We will put into operation and school in

6. We will provide authorized service

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

Separator design

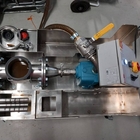

This complete filtration system is mounted on a wheeled chassis and comprises the following main parts:

- extremely strong magnetic filter

- integral on-board pump

- inlet and outlet hoses with quick lock connections for easy connection to the pipeline circuit to be cleaned.

The magnetic rods create a magnetic labyrinth that capture even the smallest ferrous particles (from 1 micron) and ensures a very high separation level.

The trapped magnetic contaminants migrate to the rear of the magnetic rods where they do not block the material flow and remain protected from wash-off until the tubes are cleaned.

Separator cleaning

As soon as the fluid inlet and outlet are closed, the inner part of the separator is taken out and put into a waste collection compartment (situated inside of the mobile filtration system). Afterwards the magnetic rods are pulled out of the protective stainless steel tubes and the captured magnetic particles fall off the protective tubes spontaneously (into the waste collection compartment). Now the magnetic filter can be reassembled and the filtration process resumed.

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

- Pressure resistance up to 10 bar

- Magnetic flux on the protective tube up to 16 000 Gauss

- Large magnetic separation area = large holding capacity

- Mobile version allows to move the filtration system easily and quickly

- Quick lock connections for easy connection to the pipeline circuit

- Mesh screen for removal of non-magnetic debris (optional)

Technical parameters

Overall dimensions of the MSP-S ANCISTRUS mobile filtration system

- Height without handle: 666 mm

- Height with handle: 943 mm

- Carriage height: 188 mm

- Length: 750 mm

- Width: 600 mm

Pump description

Calpeda AM 40-10B (power supply: 230 V, 50 Hz, motor: 2900 rpm, 0.55 kW, weight approx. 20 kg, pressure: 6 bar, IP 54, max. suction height: 12.9 m)

Calpeda AM 40-10B (power supply: 230 V, 50 Hz, motor: 2900 rpm, 0.55 kW, weight approx. 20 kg, pressure: 6 bar, IP 54, max. suction height: 12.9 m)

Hoses

4 m long inlet and outlet hoses made from oil-resistant PVC supplied with quick lock connections guaranteeing easy and fast connection of the mobile cleaning device to the pipeline circuit to be cleaned.

| Model | Input/output diameter (mm) | Datasheet |

|---|---|---|

| MSP-S 100 N ANCISTRUS | 100 | display PDF |

- A Unique Solution for Vertical Pipes: MSP-VT 250 N - CRAB Magnetic Filter for DN 250, up to 120 °C and 25 bar (case study)

- How to separate metal particles from fat on a confectionery production line? (case study)

- How to remove micron-sized metal particles from a glucose solution in pharmaceutical production? (case study)

- Separation of metals in the production of chocolate