Sorting line for separation of slightly magnetic stainless out of non-ferrous metals

Compound of the line

Spiral-chute conveyer

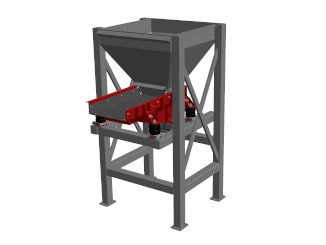

Vibrating feeder

Case study

Principal types of challenges

Conveyer with integrated MV-R 600 N radially poled magnetic roller

- there was a need of separating stainless steel out of the mixture of weakly magnetic (stainless steel) and non-magnetic materials (copper) of a small fraction

- big workable capacity (up to 2 tons/hour)

- continuous (uninterupted) production process and relatively high proportional share of stainless steel in the mixture being cleaned (5 %) generated a requirement of applying a separator with automatic cleaning

Solution provided by SOLLAU s.r.o. company: a compact line consiting of spiral-chute conveyer, vibrating feeder, MV-R 600 magnetic separator and complete wiring systém have been delivered.

SOLLAU – our products are welded by real professionals!

SOLLAU – our products are welded by real professionals!