Automated line for sorting 3D plastic waste - PET bottles

This automatic separating line is used to treat waste material kept in “yellow bins”, i.e. PET bottles, aluminum and iron cans. It is designed for a capacity of 1,200 kg/hour.

At first, the ferromagnetic cans are sorted by means of an overband magnet suspended above a belt conveyor. Aluminum cans are separated from PET bottles by an eddy current separator ECS-C RAM (the uniform layer of the material entering the eddy current separator is ensured by a vibrating feeder).

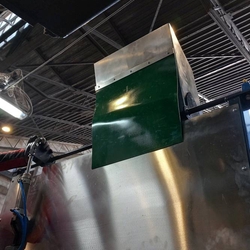

The final sorting of aluminum cans is performed using metal detectors. METRON 03 SL plate metal detector is equipped with an auto rejection diversion flap that automatically rejects the detected metal contaminants.

In the end the PET bottles are sorted by color by a NIR / VIS spectrophotometer.

The individual types of the sorted materials are pressed.

- The separation line capacity: 1.2 tons/hour

- Guaranteed separation efficiency: 95 %.

Output

The treated waste is sorted into the following material fractions:

- 3D PET bottles - PET bottles are sorted by color

- Aluminum cans

- Iron cans

The sorting line consists of the following equipment:

- Conveying systems

- DND-AC overband magnet (with automatic cleaning)

- Vibrating feeder

- Non-ferrous metal separator - ECS-C 1500 RAM eddy current separator with a concentric rare earth rotor – for conveyor belts of 1,500 mm width

- Plate metal detector METRON 03 SL 400 - including automated reject flap

- METRON 05 D tunnel metal detector

- NIR / VIS spectrophotometer

- Press

- Steel construction

- PLC controlled system