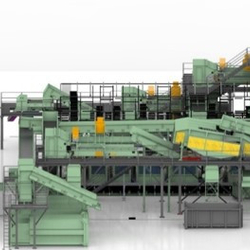

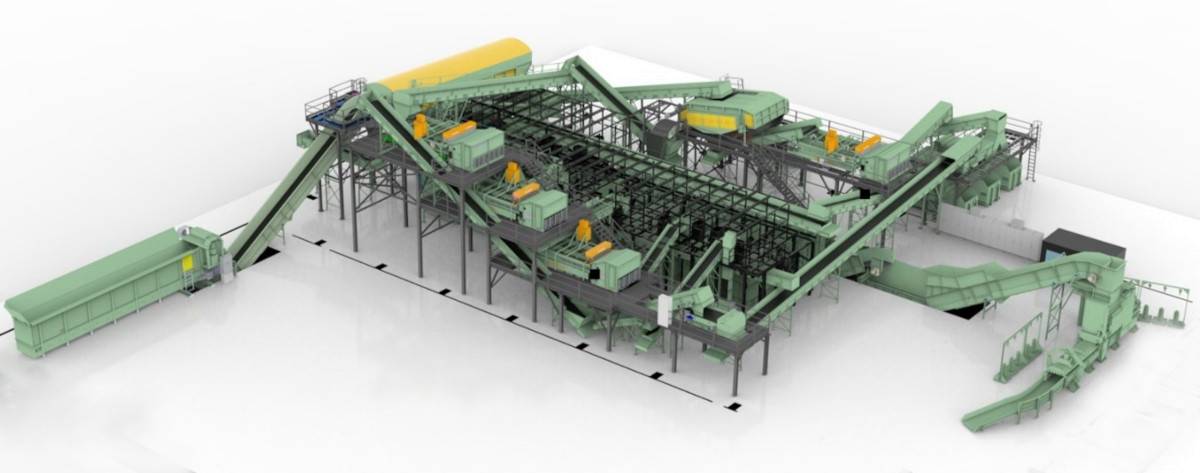

Automated sorting line for PET bottles, aluminum and iron cans

This automatic sorting line consists of more than 500 meters of conveyors (Z-shaped, straight and inclined). It is designed for a capacity of 5,000 kg/hour. The line is used to treat waste material kept in “yellow bins”, i.e. PET bottles, aluminum and iron cans.

The sorting line is monitored with a 25-camera system. All the line components are controlled by a control system with PLC outputs directly on the line and connected to the central control panel (in the process control room). The sorting line is equipped with an air-conditioned manual sorting workplace for 2 - 12 workers.

Firstly, the bales with the input material are unpacked at the line and afterwards the material passes through a trommel screen.

Separation of ferromagnetic cans is carried out by a very strong DND-AC BEAST overband magnet, which reliably separates Fe cans from other materials.

Subsequently, the material is loosened by a vibrating feeder and then the aluminum cans are separated from the PET bottles. The ECS-C eddy current separator (non-magnetic metal separator) with a 1,500 mm belt width is used for this purpose. We chose a separator of this width so that it is able to deal with the required hourly capacity.

Finally, the PET bottles are sorted by color using NIR spectrophotometers and then pressed into bales.

- The separation line capacity: 5 tons/hour

- Guaranteed separation efficiency: 95 %

Output

The treated waste is sorted into the following material fractions:

- 3D PET bottles

- Aluminum cans

- Iron cans

The sorting line consists of the following equipment:

- Transport system - 33 different conveyors (Z-shaped, angular, straight, inclined) with a total length of more than 500 m

- Bale unwrapper

- DND-AC Mx3 F BEAST overband magnet

- Vibrating feeder

- Non-ferrous metal separator - ECS-C 1500 RAM eddy current separator with an eccentric rare earth rotor – for conveyor belts of 1,500 mm width

- NIR spectrophotometer

- Trommel screen

- Automatic baler

- Accumulation storage boxes

- Pressing containers

- Air-conditioned final sorting workplace for 2 - 12 manual workers

- Steel construction

- Complex control system with PLC outputs directly on the line and connection to the control center

- 25-camera control system