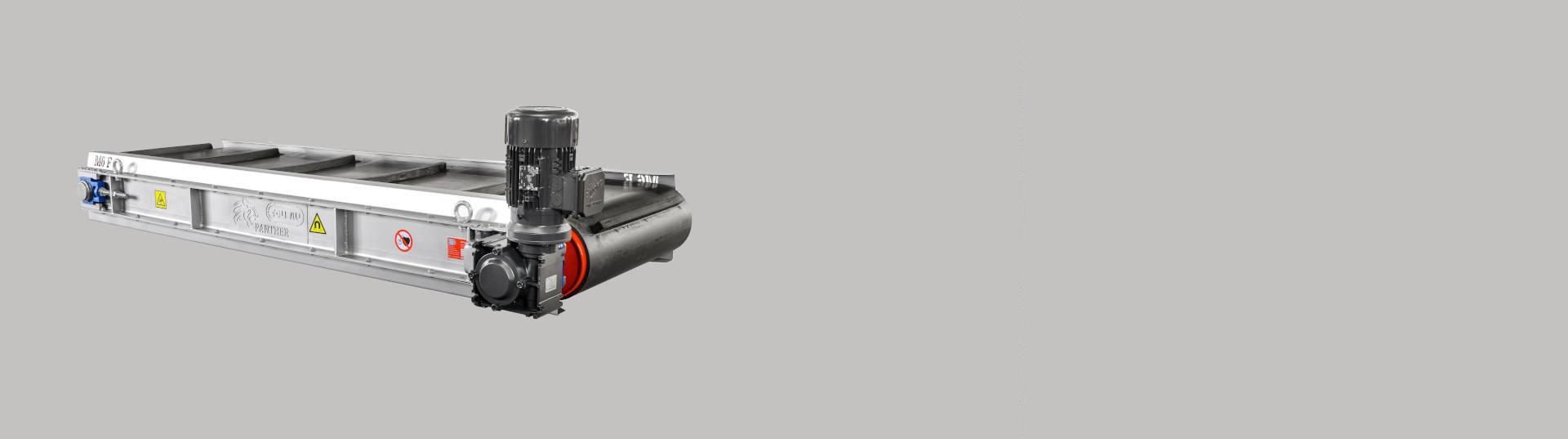

Permanent overband magnetic separators DND-AC

Overband magnet with automatic cleaning is used to separate ferrous metal contamination from bulk materials transported on a belt conveyor. It is ideal for materials heavily contaminated with ferrous particles. Thanks to the automatic cleaning, the separator operation is completely operator-free.

We fit the permanent overbands with either ferrite or very strong neodymium magnets.

For the applications where a light separator of small dimensions is required, (e. g., on mobile crushers or screeners) we can provide an overband magnet weighing only 440 kg!

For heavy industries we recommend that overbands with a magnetic induction of 1010 G (measured at the distance of 200 mm from the separator belt) are used. These very powerful overbands can be suspended 500 mm above the conveyor and separate ferrous particles from the conveyor at a speed of 3 m/s!

We know very well that different applications require different solutions. The strongest or smallest magnetic separator is not always required, the price of the product must also be taken into account. That is why we produce our overband magnets in 10 model series allowing us to provide our clients with the optimum solutions for their individual needs.

Why overband magnets by SOLLAU?

Why overband magnets by SOLLAU?

Download PDF

(Size 768 kB)

7 + 1 reasons for choosing our overband magnet

- 110-year warranty - we stand behind the quality of our magnetic separators and that is why we provide a 10-year warranty!

- 212 model series – we have a solution for every application. The basic product lines differ in the magnets that were used in their production (8 model lines are equipped with ferrite and 4 models with strong neodymium magnets). Our standard products are suitable for conveyors 500 - 2000 mm wide.

- 3Magnetic induction of 1 010 G – our strongest overbands generate a magnetic induction of up to 1010 G (at a distance of 200 mm from the separator belt)! They can be suspended at a height of 500 mm (= reachout) above the belt conveyor and separate ferrous metals sized from 0,5 to 300 mm at a speed of 3 m/s.

- 4Small compact dimensions - the small dimensions allow for an easy installation even in places with difficult access.

- 5Weight from 440 kg - our overband magnets can also be used on mobile crushers or in plants where the low weight and small dimensions are a must.

- 6All-stainless design - the overbands are made of stainless steel, guaranteeing high resistance and a long service life even in demanding conditions.

- 7No dead spots – the separators are designed in such a way that there are no dead spots between the magnetic core and the separator cover. That is why ferromagnetic particles cannot get under the separator belt and damage it.

- 8Customized production of separators - do you have any special requirements for dimensions, weight, performance or design of a magnetic separator? We will be pleased to produce a custom-made overband magnet for you that will meet all your needs. We have our design department and production line in the Czech Republic. We have long experience with the production of custom-made separators!

SOLLAU 10 year warranty

We can vouch for the quality of our magnetic separators and that is why why we provide a 10 year warranty on them! Our magnetic separators can be relied on! We are a specialist in the field of magnetic separation.

Benefits of using our separator

- Final product without iron contamination

- Protection of processing equipment (crushers, presses, screw conveyors, etc.) from damage by ferromagnetic objects (broken-off machine parts, screws, nuts, wires, etc.)

- Separation of ferrous particles

- Automatic cleaning - no operator required

Customer care

Your project will be taken care of by us from beginning up to the very end. It does not end with the order placed at us. We will provide the full support for all the time of the use of the separator.

1. We will come

2. We will align and design

3. We will make a made-to-measure product

4. We will install

5. We will put into operation and school in

6. We will provide authorized service

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

Installation of an overhead magnet

Most commonly the crossbelt magnetic separators DND-AC is suspended above and across the belt, however it is also possible to place the overbelt magnetic separator at the head of the conveyor (parallel to the belt). The kind of applied magnets depends on the position of the separator: if the magnetic separator is parallel to the conveyor belt.

Most commonly the crossbelt magnetic separators DND-AC is suspended above and across the belt, however it is also possible to place the overbelt magnetic separator at the head of the conveyor (parallel to the belt). The kind of applied magnets depends on the position of the separator: if the magnetic separator is parallel to the conveyor belt.

It is possible to use weaker magnets (as at the end of the conveyor belt the material is quite loose). On the contrary, if the overbelt magnet is suspended across the belt, we recommend that stronger magnets are applied (as the material layer on the belt might be higher and compacter).

The standard version of the overband magnetic separator DND-AC M is fitted with strong permanent ferrite magnets. However, if you need stronger magnetic force (e. g. for mobile lines, grinders, mills), we recommend that the overband magnetic separator is equipped with extremely powerful neodymium NdFeB magnets from rare earth ores. A careful interference shielding ensures that the magnetic field is concentrated only on the material on the conveyor belt.

Measuring magnetic separator power

We take pride in thorough testing each overband and measuring its magnetic performance. We know that it is important for our customers to know the magnet performance at different distances from the magnetic separator. That is why we do not state the magnetic induction values only at the magnetic core, but also at a distance of 0 to 400 mm (measured in 50 mm increments) from the separator belt.

We measure the magnetic flux density in such a way that it corresponds as faithfully as possible to real conditions. Therefore, we do not measure the magnetic induction only at the magnetic core (as some manufacturers do and artificially increase the value of the magnetic induction in this way). We measure the magnetic flux density at the above mentioned distances from the separator belt. Such piece of information is important to the customer.

The practically measured values of the magnetic induction are stated at the corresponding overbands in the website section “Gauss charts”.

Of course, we provide a test report with measured magnetic induction values for each separator.

Practical magnetic separator testing

The measured value of the magnetic induction is clear information, but for many customers, it is more important to know the kind of ferrous objects our separator can really separate. That is why we performed a set of tests to better demonstrate the strength and functionality of our overbands. We selected 13 typical ferromagnetic pieces that our customers most often need to separate (nuts, nails, wires, steel balls, etc.) and measured how the distance between the overband magnet and the ferrous objects affects the magnetic attraction (i. e., how far from the separator belt the test pieces can be trapped).

The measured value of the magnetic induction is clear information, but for many customers, it is more important to know the kind of ferrous objects our separator can really separate. That is why we performed a set of tests to better demonstrate the strength and functionality of our overbands. We selected 13 typical ferromagnetic pieces that our customers most often need to separate (nuts, nails, wires, steel balls, etc.) and measured how the distance between the overband magnet and the ferrous objects affects the magnetic attraction (i. e., how far from the separator belt the test pieces can be trapped).

See the website section “Practical testing” for this piece of information - we are sure that it will provide our client with all the data needed for the selection of the right overband magnet.

Of course, our specialists are ready to help you choose the appropriate type of the magnetic separator.

Recommendation: Connection of a magnetic plate and magnetic roll

Recommendation: Connection of a magnetic plate and magnetic roll

In order to achieve the highest possible degree of separation, it is recommended that – especially in case of a higher layer of material on the conveyor belt – the overband magnet DND is combined with the magnetic pulley MV (that is able to attract ferromagnetic particles from lower material layers).

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

Ferrite overbands - transversal placement

The main benefits of ferrite overband magnets include the following: high temperature resistence, long-term magnetic stability, affordable price, deep and very strong magnetic field (in case of stronger models). This separator is designed to be installed across the conveyor.

- Suspension height up to 280 mm

- The lightest of the ferrite models

- Separation of magnetic particles from 1 mm

Combines a standard performance with an interesting price. These separators are intended for medium-duty applications with the maximum installation height of 200 mm, and they are capable of trapping larger ferromagnetic particles (above 1 mm). A very good rate of return (price/performance ratio) is a significant benefit of this kind of plate.

| Product | Maximum width of conveyor belt (mm) | Maximum recommended installation height (mm) | Datasheet |

|---|---|---|---|

| crosswise | |||

| DND-AC M1 F PANTHER | 500 | 200 | display PDF |

| DND-AC M2 F PANTHER | 800 | 250 | display PDF |

| DND-AC M3 F PANTHER | 1000 | 280 | display PDF |

| DND-AC M4 F PANTHER | 1200 | 280 | display PDF |

| DND-AC M5 F PANTHER | 1400 | 280 | display PDF |

| DND-AC M6 F PANTHER | 1600 | 280 | display PDF |

| DND-AC M7 F PANTHER | 1800 | 280 | display PDF |

Is intended for heavy-duty users who expect from the separator a high performance even at greater depths (the maximum installation height is 320 mm).

| Product | Maximum width of conveyor belt (mm) | Maximum recommended installation height (mm) | Datasheet |

|---|---|---|---|

| crosswise | |||

| DND-AC Ms2 F JAGUAR | 800 | 270 | display PDF |

| DND-AC Ms3 F JAGUAR | 1000 | 300 | display PDF |

| DND-AC Ms4 F JAGUAR | 1200 | 320 | display PDF |

| DND-AC Ms5 F JAGUAR | 1400 | 320 | display PDF |

| DND-AC Ms6 F JAGUAR | 1600 | 320 | display PDF |

| DND-AC Ms7 F JAGUAR | 1800 | 320 | display PDF |

| DND-AC Ms8 F JAGUAR | 2000 | 320 | display PDF |

Is a model intended for the installation height up to 340 mm (it is also wider, what is its another advantage).

| Product | Maximum width of conveyor belt (mm) | Maximum recommended installation height (mm) | Datasheet |

|---|---|---|---|

| crosswise | |||

| DND-AC Mp2 F LION | 800 | 290 | display PDF |

| DND-AC Mp3 F LION | 1000 | 320 | display PDF |

| DND-AC Mp4 F LION | 1200 | 340 | display PDF |

| DND-AC Mp5 F LION | 1400 | 340 | display PDF |

| DND-AC Mp6 F LION | 1600 | 340 | display PDF |

| DND-AC Mp7 F LION | 1800 | 340 | display PDF |

| DND-AC Mp8 F LION | 2000 | 340 | display PDF |

Is designated for very demanding applications and for removal of ferromagnetic particles from depths of up to 400 mm.

| Product | Maximum width of conveyor belt (mm) | Maximum recommended installation height (mm) | Datasheet |

|---|---|---|---|

| crosswise | |||

| DND-AC Mm2 F TIGER | 800 | 320 | display PDF |

| DND-AC Mm3 F TIGER | 1000 | 350 | display PDF |

| DND-AC Mm4 F TIGER | 1200 | 400 | display PDF |

| DND-AC Mm5 F TIGER | 1400 | 400 | display PDF |

| DND-AC Mm6 F TIGER | 1600 | 400 | display PDF |

| DND-AC Mm7 F TIGER | 1800 | 400 | display PDF |

| DND-AC Mm8 F TIGER | 2000 | 400 | display PDF |

Is the strongest of all SOLLAU magnetic overband separators. Magnetic induction of these devices is at the limit of the capabilities of the strongest permanent magnets and can only be surpassed by electromagnetic separators. This series is intended for the most challenging separation from extreme depths and high and heavy material layers. The maximum suspension height of these devices is 450 mm (an interesting fact: the strongest ferrite DND-AC Mx F series is approximately five times heavier than the lightest DND-AC M F series!).

| Model* | Maximum width of conveyor belt (mm) | Maximum recommended installation height (mm) | Datasheet |

|---|---|---|---|

| crosswise | |||

| DND-AC Mx3 F BEAST | 1000 | 500 | display PDF |

| DND-AC Mx4 F BEAST | 1200 | 500 | display PDF |

| DND-AC Mx5 F BEAST | 1400 | 500 | display PDF |

| DND-AC Mx6 F BEAST | 1600 | 500 | display PDF |

| DND-AC Mx7 F BEAST | 1800 | 500 | display PDF |

| DND-AC Mx8 F BEAST | 2000 | 500 | display PDF |

- Budget version (attractive price/performance ratio)

- Magnetically as strong as the branded overband DND-AC Ms F JAGUAR

- Suspension height up to 320 mm

- Separation of magnetic particles from 1 mm

Overband magnetic separator DND-AC EKO is a low-cost variant of an overband magnet. From the magnetic point of view there is no difference between the standard version DND-AC and the economic version DND-AC EKO.

Both generate the same magnetic induction (what is quite exceptional, as the economic models of our competitors are generally magnetically weaker in comparison with their standard models). On the other hand, the clients acquiring our DND-AC EKO version have to accept the fact that this model is equipped with the engine CANTONI and with the gearbox VARVEL, there are unprotected bearings and only the bottom part of the separator is protected by metal sheets.

DND-AC EKO is designed to handle product stream with a high content of ferromagnetic particles (exceeding the capacities of the manually cleaned magnetic plates). This separator can capture in a quick and easy way valuable ferromagnetic particles from a product stream and at the same time the overband magnetic plate with automatic cleaning protects your machinery (shredders, mills, grinders, screw conveyors etc.) that subsequently treat the material. The tramp ferrous metal extracted from the conveyor is removed by a heavy duty rubber belt into a skip or a collection bin at the side of the conveyor.

| Model | Recommended for a belt with a maximum width (mm) | Maximum recommended installation height (mm) | Datasheet |

|---|---|---|---|

| crosswise | |||

| DND-AC Ms2 F EKO | 800 | 270 | display PDF |

| DND-AC Ms3 F EKO | 1000 | 300 | display PDF |

| DND-AC Ms4 F EKO | 1200 | 320 | display PDF |

| DND-AC Ms5 F EKO | 1400 | 320 | display PDF |

| DND-AC Ms6 F EKO | 1600 | 320 | display PDF |

| DND-AC Ms7 F EKO | 1800 | 320 | display PDF |

| DND-AC Ms8 F EKO | 2000 | 320 | display PDF |

Some products from this model family are available for immediate purchase. We are constantly extending the offer of our magnetic separators in stock so that we can deliver them to you immediately. Please, contact our dealer to inform for their current availability.

Neodymium overbands - transversal placement

An extremely strong (but relatively short) magnetic field and a low weight are the most significant benefits of neodymium overband separators. That is why the application of the neodymium separators is preferred at the places where it would not be possible to use heavy ferrite magnets or where a very high separation efficiency at shallower depths is required (e. g., in cases of mobile crushing and recycling lines). This separator is designed to be installed across the conveyor.

Is the lightest series intended for the maximum suspension height of 300 mm. This separator is even able to trap Fe particles smaller than 1 mm (at shallower depths).

| Product | Maximum width of conveyor belt (mm) At crosswise installation above the conveyor | Maximum recommended installation height (mm) | Datasheet |

|---|---|---|---|

| DND-AC N1 JACKAL | 500 | 300 | display PDF |

| DND-AC N2 JACKAL | 700 | 300 | display PDF |

| DND-AC N3 JACKAL | 1000 | 300 | display PDF |

| DND-AC N4 JACKAL | 1200 | 300 | display PDF |

| DND-AC N5 JACKAL | 1400 | 300 | display PDF |

| DND-AC N6 JACKAL | 1600 | 300 | display PDF |

| DND-AC N7 JACKAL | 1800 | 300 | display PDF |

- Separator constantly in stock (immediately available)

- Twin pole neodymium variant with a ferrite releasing pole

- Suspension height up to 300 mm

- Separation of magnetic particles from 0,5 mm

Is available in 2-pole version with discharge ferrite pole.

| Product | Maximum width of conveyor strand (mm) At crosswise installation above the conveyor | Maximum recommended installation height (mm) | Datasheet |

|---|---|---|---|

| DND-AC NKS1 JACKAL II | 900 | 300 | display PDF |

Some products from this model family are available for immediate purchase. We are constantly extending the offer of our magnetic separators in stock so that we can deliver them to you immediately. Please, contact our dealer to inform for their current availability.

Is a stronger neodymium variant (with a maximum installation height of 350 mm), intended for medium-duty applications. Its benefits include: a high magnetic induction (at a short distance), a separation of smaller Fe particles and a low weight.

| Product | Maximum width of conveyor belt (mm) At crosswise installation above the conveyor | Maximum recommended installation height (mm) | Datasheet |

|---|---|---|---|

| DND-AC Ns1 HYENA | 500 | 350 | display PDF |

| DND-AC Ns2 HYENA | 700 | 350 | display PDF |

| DND-AC Ns3 HYENA | 1000 | 350 | display PDF |

| DND-AC Ns4 HYENA | 1200 | 350 | display PDF |

| DND-AC Ns5 HYENA | 1400 | 350 | display PDF |

| DND-AC Ns6 HYENA | 1600 | 350 | display PDF |

| DND-AC Ns7 HYENA | 1800 | 350 | display PDF |

Some products from this model family are available for immediate purchase. We are constantly extending the offer of our magnetic separators in stock so that we can deliver them to you immediately. Please, contact our dealer to inform for their current availability.

This is the strongest neodymium model, particularly intended for mobile applications where an extremely high magnetic induction at shallower material depths is needed. Maximum installation height: 380 mm.

| Product | Maximum width of conveyor belt (mm) At crosswise installation above the conveyor | Maximum recommended installation height (mm) | Datasheet |

|---|---|---|---|

| DND-AC Nm2 WOLF | 700 | 380 | display PDF |

| DND-AC Nm3 WOLF | 1000 | 380 | display PDF |

| DND-AC Nm4 WOLF | 1200 | 380 | display PDF |

| DND-AC Nm5 WOLF | 1400 | 380 | display PDF |

| DND-AC Nm6 WOLF | 1600 | 380 | display PDF |

| DND-AC Nm7 WOLF | 1800 | 380 | display PDF |

Some products from this model family are available for immediate purchase. We are constantly extending the offer of our magnetic separators in stock so that we can deliver them to you immediately. Please, contact our dealer to inform for their current availability.

Ferrite plates - longitudinal placement

The main benefits of ferrite overband magnets include the following: high temperature resistence, long-term magnetic stability, affordable price, deep and very strong magnetic field (in case of stronger models).

This separator is designed to be installed longitudinally with the conveyor. Thanks to the installation above the end of the conveyor belt, the material is separated as soon as it falls from the end conveyor roller and is thus more permeable. This has a positive impact on the quality of the magnetic separation. Sometimes it can be the only suitable solution of magnetic separation, e.g. for materials with poor bulk properties or when the layer of material transported by the conveyor is high.

We recommend replacing the end conveyor roller with a non-magnetic one to increase the efficiency of the magnetic separator and prevent unwanted magnetization of the conveyor roller.

This range of magnetic plates is designed for the separation of material with a medium layer height - the hanging height is 320 mm.

| Product | Maximum width of conveyor belt (mm) | Maximum recommended installation height (mm) | Datasheet |

|---|---|---|---|

| longwise | |||

| DND-AC Ms2 F IN LYNX | 800 | 320 | display PDF |

| DND-AC Ms3 F IN LYNX | 1000 | 320 | display PDF |

| DND-AC Ms4 F IN LYNX | 1200 | 320 | display PDF |

| DND-AC Ms5 F IN LYNX | 1400 | 320 | display PDF |

| DND-AC Ms6 F IN LYNX | 1600 | 320 | display PDF |

This is the most powerful model series of separators for longitudinal placement with a hanging height of an incredible 500 mm!

This range of magnetic plates is designed for the separation of material with a large layer height.

| Product | Maximum width of conveyor belt (mm) | Maximum recommended installation height (mm) | Datasheet |

|---|---|---|---|

| longwise | |||

| DND-AC Mx4 F IN PUMA | 1200 | 500 | display PDF |

| DND-AC Mx5 F IN PUMA | 1400 | 500 | display PDF |

| DND-AC Mx6 F IN PUMA | 1600 | 500 | display PDF |

DND-AC M F PANTHER

DND-AC Ms F JAGUAR

DND-AC Mm F TIGER

DND-AC Ms F EKO

DND-AC N JACKAL

DND-AC Nm WOLF

DND-AC M F PANTHER

- DND-AC M1 F PANTHER

- DND-AC M2 F PANTHER

- DND-AC M3 F PANTHER

- DND-AC M4 F PANTHER

- DND-AC M5 F PANTHER

- DND-AC M6 F PANTHER

- DND-AC M7 F PANTHER

DND-AC Ms F JAGUAR

- DND-AC Ms2 F JAGUAR

- DND-AC Ms3 F JAGUAR

- DND-AC Ms4 F JAGUAR

- DND-AC Ms5 F JAGUAR

- DND-AC Ms6 F JAGUAR

- DND-AC Ms7 F JAGUAR

- DND-AC Ms8 F JAGUAR

DND-AC Mp F LION

- DND-AC Mp2 F LION

- DND-AC Mp3 F LION

- DND-AC Mp4 F LION

- DND-AC Mp5 F LION

- DND-AC Mp6 F LION

- DND-AC Mp7 F LION

- DND-AC Mp8 F LION

DND-AC Mm F TIGER

- DND-AC Mm2 F TIGER

- DND-AC Mm3 F TIGER

- DND-AC Mm4 F TIGER

- DND-AC Mm5 F TIGER

- DND-AC Mm6 F TIGER

- DND-AC Mm7 F TIGER

- DND-AC Mm8 F TIGER

DND-AC Mx F BEAST

- DND-AC Mx3 F BEAST

- DND-AC Mx4 F BEAST

- DND-AC Mx5 F BEAST

- DND-AC Mx6 F BEAST

- DND-AC Mx7 F BEAST

- DND-AC Mx8 F BEAST

DND-AC Ms F EKO

DND-AC N JACKAL

- DND-AC N1 JACKAL

- DND-AC N2 JACKAL

- DND-AC N3 JACKAL

- DND-AC N4 JACKAL

- DND-AC N5 JACKAL

- DND-AC N6 JACKAL

- DND-AC N7 JACKAL

DND-AC N JACKAL II

DND-AC Ns HYENA

- DND-AC Ns1 HYENA

- DND-AC Ns2 HYENA

- DND-AC Ns3 HYENA

- DND-AC Ns4 HYENA

- DND-AC Ns5 HYENA

- DND-AC Ns6 HYENA

- DND-AC Ns7 HYENA

DND-AC Nm WOLF

- JACKAL is in action! Strong, lightweight and immediately available! (case study)

- Separation of metals from Solid Recovered Fuels (SRF) - the most powerful separator on a special price! (case study)

- Separation of magnetic and non-magnetic metals in a municipal incineration plant (case study)

- Separation of iron and aluminum cans from non-metallic contamination (case study)

Why overband magnets by SOLLAU?

Why overband magnets by SOLLAU?

Download PDF

(Size 768 kB)

Which industrial branches can the overband magnets be used in?

This self-cleaning magnetic separator finds use in recycling, mining, plastic, glass and wood industries.